Hole DT21-02: 0.50 m core length grading 426 g/t Silver, 6.5 g/t Gold, 17.1% Lead + Zinc

Hole DT21-03: 1.90 m core length grading 952 g/t Silver, 38.2 g/t Gold, 9.2% Lead + Zinc

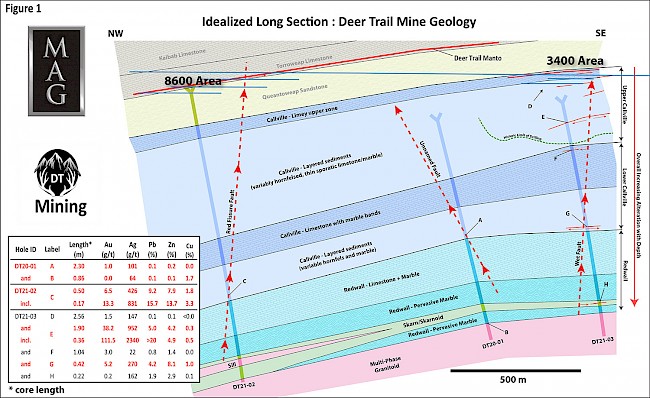

Vancouver, B.C. MAG Silver Corp. (TSX / NYSE American: MAG) (“MAG” or “MAG Silver”) is pleased to report results from Phase 1 drilling on its Deer Trail Carbonate Replacement Deposit (CRD) Project in central Utah, USA (the “Deer Trail Project” or the “Project”). Phase 1 saw the completion of three holes (3,927 metres (“m”)) drilled from surface spaced along a 1.5 km long corridor (Figure 1). Phase 1 successfully fulfilled all three of its planned objectives by:

- Confirming the presence of a thick section of more favorable carbonate host rocks (the predicted “Redwall Limestone” or “Redwall”) below the Deer Trail Mine;

- Confirming and projecting two suspected mineralization feeder structures to depth; and

- Intercepting high-grade mineralization related to those structures in host rocks below what was historically known.

Notably, all three holes bottomed within multi-phase porphyritic granitoids affected by later sericite-pyrite alteration with modest Copper and Silver mineralization along their upper contacts (including 0.86m grading 1.7% Copper and 64 g/t Silver in hole DT20-01). The overall features suggest that this mineralization was sourced from a later intrusive phase.

The principal goal of Phase 1 drilling was to locate the Redwall Limestone, a thick, clean limestone unit hypothesized to be a more favorable host rock than the thinly layered Callville Formation, which hosts the deepest historically known mineralization in the mine area. The likely presence of the Redwall was indicated by regional occurrences and all three holes cut 215 m – 320 m of highly altered Redwall before bottoming in granitoid intrusions. All three holes cut high-grade sulphide mineralization in/near projected feeder structures within the Callville before reaching the Redwall (Table 1, Figure 1). DT21-02 intercepted 0.50 m (core length) of sulphides grading 426 grams per tonne (“g/t”) (12.4 ounces per ton (“opt”) Silver, 6.5 g/t (0.2 opt) Gold, and 17.1% Lead plus Zinc within a 3.5 m breccia zone along the Red Fissure Fault; principal feeder to the historic Deer Trail Manto. DT21-03 cut 1.90 m (core length) of manto-style (bedding parallel) sulphides grading 952 g/t Silver (27.8 opt), 38.2 g/t (1.1 opt) Gold, and 9.2% Lead plus Zinc close to the Wet Fault, a principal feeder to the 3400 Area manto zone. DT20-01 was designed simply to locate the Redwall at shallow depth, but before reaching the Redwall, it cut a ~20 m (core length) feeder zone in the Callville containing a 2.30 m (core length) mineralized strand that reported 1.0 g/t Gold and 101 g/t Silver.

Phase 2 drilling commenced on August 20, 2021. The first hole of Phase 2 is an offset of DT21-03 designed to test the Wet fault 150 m deeper where it cuts through the Redwall.

“We are very pleased to have our first holes in this promising, district-scale play satisfy all three of our initial objectives, including finding high-grade, silver and gold-rich mineralization just above what should be excellent host rocks”, said George Paspalas, MAG Silver’s President and CEO. “These initial results validate our exploration model and the high silver grades at depth seem to indicate very large-scale zoning, which strongly reinforces our belief that the Deer Trail system is extensive and well mineralized. We eagerly look forward to the results of the ongoing Phase 2 drilling.”

Sustainability and ESG

Achieving excellence in Environmental, Social and Governance (“ESG”) practices is a core component of MAG’s business – it is not only the right thing to do, but also essential to the future growth and profitability of the Company. MAG is committed to maintaining best-in-class corporate governance practices and having a positive environmental and social impact. MAG’s commitment to ‘zero harm’ prioritizes the health, safety and well-being of its people and the communities in which they live and work. At the Deer Trail Project, MAG’s proactive safety programs have resulted in zero lost-time injuries to date. MAG takes a ‘shared value’ approach to local development activities to promote sustainable economic and social benefits. MAG has a robust stakeholder engagement program which includes consultation with local stakeholders, municipal and regional leaders, and government agencies. MAG is committed to wise environmental stewardship and fully complies with, and strives to exceed, all applicable laws and regulations. Since acquiring the Deer Trail Project, MAG has proactively remediated legacy environmental deficiencies and safety hazards.

Table 1: Phase 1 Drilling Highlights

| HOLE ID | FROM (M) |

TO (M) |

CORE LENGTH (M)1 |

AU (G/T)2 |

AG (G/T)2 |

PB (%) |

ZN (%) |

CU (%) |

|---|---|---|---|---|---|---|---|---|

| DT20-01 | 679.24 | 681.54 | 2.30 | 1.0 | 101 | 0.1 | 0.2 | <0.1 |

| and | 1147.42 | 1148.28 | 0.86 | 0.0 | 64 | 0.1 | 0.1 | 1.7 |

| DT21-02 | 1161.23 | 1161.73 | 0.50 | 6.5 | 426 | 9.2 | 7.9 | 1.8 |

| incl. | 1161.23 | 1161.40 | 0.17 | 13.3 | 831 | 15.7 | 13.7 | 3.3 |

| DT21-03 | 261.51 | 264.07 | 2.56 | 1.5 | 147 | 0.1 | 0.1 | <0.1 |

| and | 443.20 | 445.10 | 1.90 | 38.2 | 952 | 5.03 | 4.2 | 0.3 |

| incl. | 444.74 | 445.10 | 0.36 | 111.5 | 2340 | >203 | 4.9 | 0.5 |

| and | 514.45 | 515.49 | 1.04 | 3.0 | 22 | 0.8 | 1.4 | <0.1 |

| and | 746.70 | 747.12 | 0.42 | 5.2 | 270 | 4.2 | 8.1 | 1.0 |

| and | 1043.98 | 1044.20 | 0.22 | 0.2 | 162 | 1.9 | 2.9 | 0.1 |

1 core length as cut; true thickness indeterminate

2 grams per tonne

3 includes single >20% pending overlimit

Phase 1 Results (in priority order, Table 1, Figure 1):

- Confirmed the presence of thick sections of favorable Redwall Limestone carbonate host rocks in all three holes along a 1.5 km transect. Regionally the thick, clean limestones of the Redwall Limestone and its stratigraphic equivalents host significant replacement deposits (e.g. Leadville, CO), so it is hypothesized to be a more favorable host for laterally extensive mineralization than the thin, interbedded shales-sandstones-limestones of the Callville Formation, which hosts the historically deepest known mineralization in the Deer Trail Mine. The Redwall does not crop out in the project area, nor was it intercepted in prior drilling campaigns, but regional geologic data indicated it should lie a few hundred metres below the mine. As predicted, all three holes cut 215 m – 320 m of strongly recrystallized and locally skarn-altered Redwall Limestone beneath the Callville. Notably, in contrast to the known mineralized upper portion of the Callville, which is characterized by thin limestones interbedded with thicker sandstones and shales, drilling shows the lower Callville contains an approximately 125 m thick zone dominated by clean limestones only ~230 m below the mine. These should also be viable hosts for large-scale mineralization. The fact that the mineralization cut in DT21-02 lies in lowermost Callville limestone supports that inference.

- Traced the known feeder structures to depth towards those more favorable host rocks. DT21-02 successfully cut the “Red Fissure” fault (the main feeder structure for the principal Deer Trail manto mineralization) approximately 740 m below the mine. This is still within the lower Callville, but only about 50 m above massive Redwall Limestone. DT21-03 cut bedding-parallel, manto-style mineralization that appears to lie very close to the projection of the Wet fault, a principal feeder to manto mineralization in the lower “3400 Area” of the mine. The traces of the Red Fissure and Wet faults were projected 740 m and 950 m respectively below mine exposures, which strongly suggests these faults are continuous and fairly planar. Notably, a number of additional potential feeder structures, marked by thin mineralization, brecciation, very well developed “fugitive calcite” and skarn alteration, were cut in all three holes. Several of these intercepts (especially at 746 m and 1043 m depth in DT21-03 (Table 1)) may warrant follow-up drilling in Phase 2.

- Discovered mineralization related to those structures and host rocks at depth. DT21-02 and 03 both cut high-grade, multi-stage massive sulphide replacement mineralization in Callville limestones above the Redwall Limestone. Notably, the silver grades in both holes are comparable to those of the historic Deer Trail massive sulfides, which suggests limited vertical zoning despite being up to 740 m deeper in the system. DT21-02 appears to have cut mineralization directly within the Red Fissure fault, while DT21-03 appears to be manto-style mineralization fed from the nearby Wet fault. Phase 2 drilling is targeting these mineralized structures down dip within the clean carbonates of the Redwall.

High-Grade Sulphide Intercepts

DT21-02 cut 0.50 m (core length) of massive galena, sphalerite and pyrite, grading 426 g/t Silver, 6.5 g/t Gold, 17.1% Lead plus Zinc in Callville Formation limestones, approximately 50 m above the Redwall. The mineralization occurs within a larger 3.5 m wide breccia zone that lies along the projection of the Red Fissure (host to the principal Deer Trail Manto mineralization). The sulphides are clearly multi-phase, showing several stages of mineralization, disruption, and remineralization. The Callville limestones around the mineralization are strongly marbleized with local skarn and skarnoid development. The underlying Redwall Limestone is even more strongly marbleized, and skarn altered with alteration in all holes increasing with depth.

DT21-03 cut 1.90 m (core length) of bedding-parallel, manto-style galena, sphalerite and pyrite mineralization grading 952 g/t Silver, 38.2 g/t Gold, and 9.2% Lead plus Zinc in the Callville Formation. This intercept is 125 m downdip from the 3400 Area, near the projection of the Wet fault, one of the feeders to the 3400 Area mineralization. The sulphides are clearly multi-phase, showing several stages of mineralization, disruption and remineralization. The surrounding limestone is strongly marbleized with local skarn and skarnoid development.

Porphyry Related Mineralized Intercepts

All three holes bottomed in pervasively potassically-altered multi-phase granitoid porphyries. Limited cross-cutting, texturally destructive sericite-pyrite alteration, with associated copper mineralization, is localized along the contact with the immediately overlying Redwall Limestone. The Redwall displays weak to moderate skarn development within broad zones (>100 m) of bleached white marble in all three holes. Sulphides associated with this alteration consist of disseminated pyrite and chalcopyrite in the contact zone and chalcopyrite veinlets in the intrusion along and within a few meters of the contact. The strongest mineralization was cut in DT20-01, which reported 0.86 m (core length) grading 1.65% Copper and 64 g/t Silver within skarn at the very top of the intrusion. The other two holes reported strongly anomalous copper along their contacts with the Redwall. Mineralization and alteration in all three holes diminish rapidly below the limestone contact, which strongly suggests hydrothermal fluids from an unknown source followed the contact zone for some distance.

About Deer Trail

The silver-rich Deer Trail Carbonate Replacement Deposit (CRD) Project in Piute County, Utah encompasses the historic Deer Trail Mine and the adjoining Alunite Ridge area (approximately 5,700 Ha). MAG has consolidated these properties for the first time since the early 1980s, allowing us to apply an integrated district-scale exploration approach based on the continuum of mineralization styles from CRD through Skarn to Porphyry Copper-Molybdenum shown by many related systems worldwide. This model suggests that the high-grade silver, gold, lead, zinc and copper CRD sulphides of the Deer Trail Mine are linked by continuous mineralization to a Porphyry Copper-Molybdenum centre at some distance from the mine. Initial work has focused on tracing the known high-grade CRD mineralization of the historic mine to depth into more favorable host rocks while surface work is tightening localization of the probable porphyry intrusive source for the system. The Deer Trail Project is headed by Dr. Lex Lambeck an A.I.P.G. Certified Professional Geologist with over 15 years of relevant experience in CRD exploration.

Quality Assurance and Control: The samples (half core) are shipped directly in security-sealed bags to ALS-Laboratories preparation facilities in Elko, Nevada, or Tucson, Arizona, USA (Certification ISO/IEC 17025:2017). Samples shipped also included intermittent QA/QC standards and blanks. Pulp samples are subsequently shipped to ALS Global – Geochemistry Analytical Lab in North Vancouver, Canada for analysis. The remaining half core is placed back into the core boxes and is retained on site in a secured core storage facility.

Qualified Persons: Dr. Peter Megaw, Ph.D., C.P.G., and Lyle Hansen, M.Sc., P.Geo have acted as the qualified persons as defined in National Instrument 43-101 for this disclosure and supervised the preparation of the technical information in this release. Dr. Megaw has a Ph.D. in geology and more than 36 years of relevant experience focussed on silver and gold exploration in Mexico. He is a Certified Professional Geologist (CPG 10227) by the American Institute of Professional Geologists and an Arizona Registered Geologist (ARG 21613). Dr. Megaw is not independent as he is Chief Exploration Officer and a Shareholder of MAG. Dr. Megaw is satisfied that the results are verified based on an inspection of the core and underground exposures, a review of the sampling procedures, the credentials of the professionals completing the work and the visual nature of the silver and base metal sulphides within a district where he is familiar with the style and continuity of mineralization. Mr. Hansen has a Masters in Geology from UBC and is a registered Professional Geologist with Engineers and Geoscientists BC (149624) and has more than 11 years experience in epithermal veins. Mr. Hansen is not independent as he is Geotechnical Director of MAG.

About MAG Silver Corp. (www.magsilver.com )

MAG Silver Corp. (MAG: TSX / NYSE A) is a Canadian development and exploration company focused on becoming a top-tier primary silver mining company by exploring and advancing high-grade, district scale, silver-dominant projects in the Americas. Its principal focus and asset is the Juanicipio Project (44%), being developed in a Joint Venture partnership with Fresnillo Plc (56%), the Operator. Juanicipio is located in the Fresnillo Silver Trend in Mexico, the world’s premier silver mining camp, and the Joint Venture is currently developing an underground mine and constructing a 4,000 tonnes per day processing plant which is expected to commence commissioning in Q4 2021. Underground mine production of development material commenced in Q3 2020, and an expanded exploration program is in place targeting multiple highly prospective targets both at Juanicipio by the Joint Venture and by MAG at the Deer Trail 100% earn-in project in Utah.

For further information on behalf of MAG Silver Corp.

Contact Michael J. Curlook, VP Investor Relations and Communications

Phone: (604) 630-1399

Toll Free: (866) 630-1399

Website: www.magsilver.com

Email: info@magsilver.com

Neither the Toronto Stock Exchange nor the NYSE American has reviewed or accepted responsibility for the accuracy or adequacy of this press release, which has been prepared by management.

This release includes certain statements that may be deemed to be “forward-looking statements” within the meaning of the US Private Securities Litigation Reform Act of 1995. All statements in this release, other than statements of historical facts are forward looking statements, including statements that address future mineral production, reserve potential, exploration drilling, exploitation activities and events or developments. Forward-looking statements are often, but not always, identified by the use of words such as “seek”, “anticipate”, “plan”, “continue”, “estimate”, “expect”, “may”, “will”, “project”, “predict”, “potential”, “targeting”, “intend”, “could”, “might”, “should”, “believe” and similar expressions. These statements involve known and unknown risks, uncertainties and other factors that may cause actual results or events to differ materially from those anticipated in such forward-looking statements. Although MAG believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the forward-looking statements. Factors that could cause actual results to differ materially from those in forward-looking statements include, but are not limited to, changes in commodities prices, changes in mineral production performance, exploitation and exploration successes, continued availability of capital and financing, and general economic, market or business conditions, political risk, currency risk and capital cost inflation. In addition, forward-looking statements are subject to various risks, including that data is incomplete and considerable additional work will be required to complete further evaluation, including but not limited to drilling, engineering and socio-economic studies and investment. The reader is referred to the Company’s filings with the SEC and Canadian securities regulators for disclosure regarding these and other risk factors. There is no certainty that any forward-looking statement will come to pass and investors should not place undue reliance upon forward-looking statements.

Please Note: Investors are urged to consider closely the disclosures in MAG’s annual and quarterly reports and other public filings, accessible through the Internet at www.sedar.com and www.sec.gov LEI: 254900LGL904N7F3EL14